Introduction:

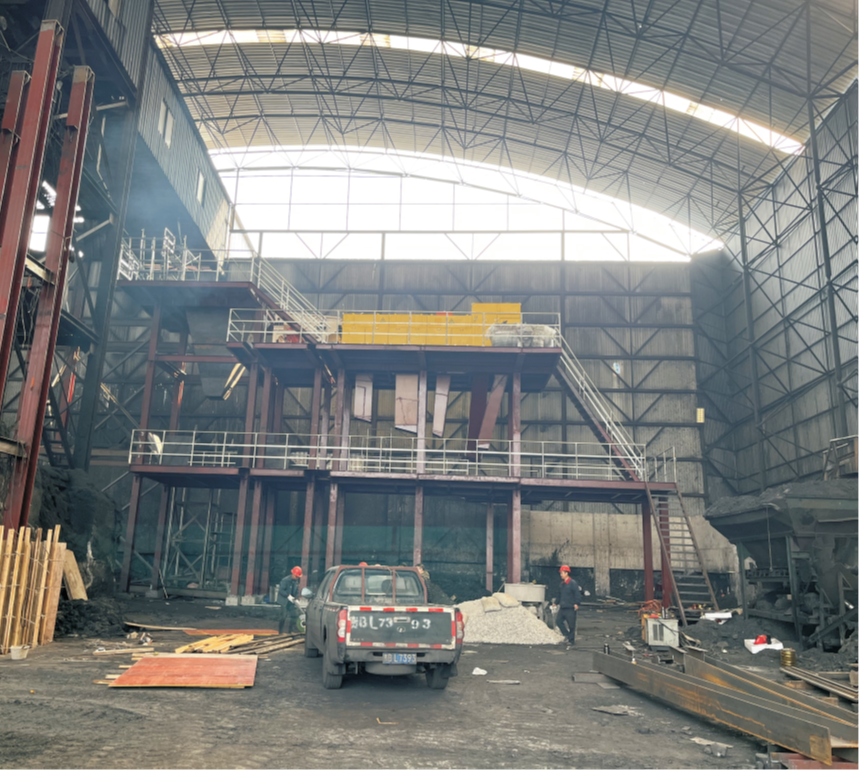

Guineng Group Hebian Coal Industry is located in Duge Town, Shuicheng District, Liupanshui City, Guizhou Province. With a production capacity of 900,000 tons per year, the mine faces challenges due to high Reject content and poor quality of raw coal, leading to low market prices and the necessity of transporting coal to distant preparation plants for washing. To address these issues, Hebian Coal Mine has implemented a dry coal sorting system at the wellhead.

Project Overview:

Location: Duge Town, Shuicheng District, Liupanshui City, Guizhou Province

Production Capacity: 0.9 Mt/a

Challenges: High Reject content, low-quality raw coal, high transportation and washing costs

Solution:

Dry Coal Sorting System:

To improve efficiency and reduce costs, Hebian Coal Mine installed a dry coal sorting system at the wellhead, aimed at pre-discharge of Reject from the raw coal. This approach offers several benefits:

Reject Pre-Discharge: Pre-sorting Reject at the wellhead reduces the volume of waste transported and processed.

Cost Reduction: Minimizes transportation and subsequent washing costs by reducing the Reject content before it reaches the preparation plant.

Equipment and Performance:

Processing Particle Size: 50-300mm

Machine Used: 1 FHG-1600-X Golden Coal Series dry coal sorting machine

Single Machine’s Processing Capacity: >180 t/h

Sorting Result:

Coal in Reject: <1%

Reject Discharge Rate: >95%

Benefits and Outcomes:

Enhanced Efficiency: Significant reduction in the volume of waste transported and processed.

Cost Savings: Lower transportation and washing costs due to efficient Reject pre-discharge.

Improved Coal Quality: Higher market value for the processed coal due to improved quality and reduced impurities.

Conclusion:

The installation of the dry coal sorting system at Guineng Group Hebian Coal Industry has effectively addressed the challenges of high Reject content and poor raw coal quality. By pre-discharging Reject at the wellhead, the mine has achieved significant cost savings and improved the quality and marketability of its coal.