COAL GASIFICATION-ASSOCIATED ADVANTAGES AND CHALLENGES (Overground and Underground Gasifiers)

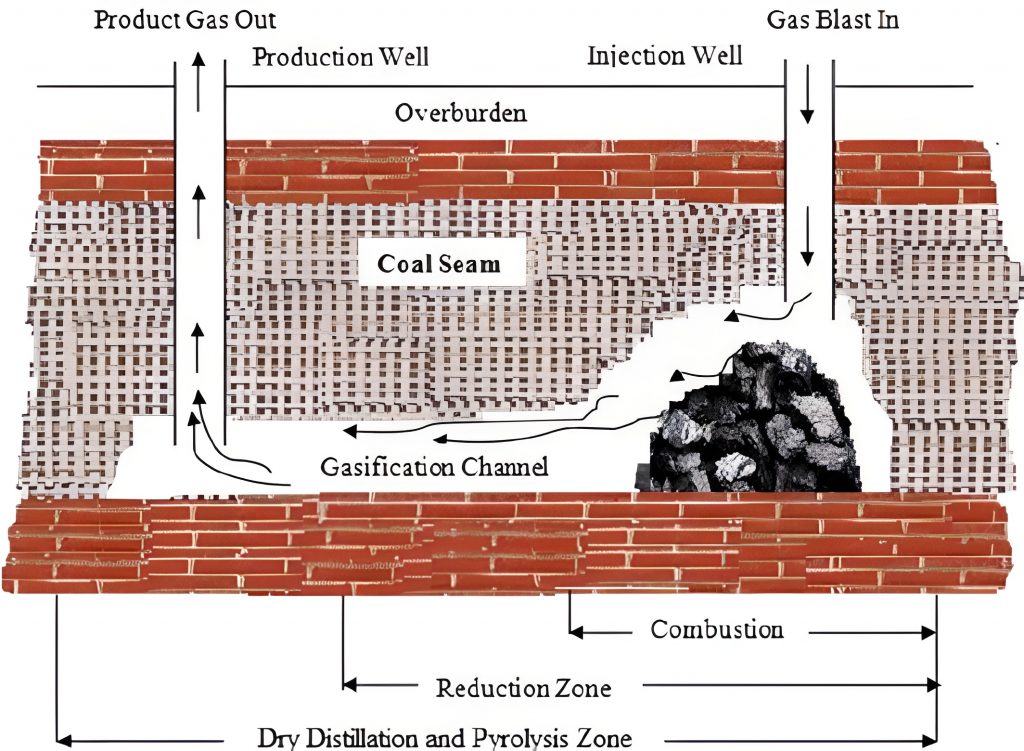

Authors are with John Finlay India Pvt Ltd: Om Prakash- Advisor Coal & Minerals Beneficiation Aadil Keshwani- Managing Director Preamble: We are in an era of depleting resources for petroleum and natural gas due to the rapid growth of our population and demand for gradually improving the quality of our day-to-day life. The invention of Coal Gasification is to make up for the shortage of liquid and gaseous fuels. Coal Gasification is a technical process of converting coal into synthesis gas known as SYNGAS a mixture of carbon monoxide, hydrogen, carbon dioxide, and other minor constituents by reacting the coal with oxygen, steam, and carbon dioxide. This process takes place in a gasifier at a pressure greater than 30 Bar and a temperature typically reaching 1225 Degrees C. TYPICAL INTEGRATED COMBINED CYCLE OF COAL GASIFICATION: The undermentioned typical equipment flow diagram depicts the use of SYNGAS for the generation of electrical power with the following features: Secondly, the hot combustion gas from the gas turbine is sent to the heat recovery steam generator which produces steam, which in turn drives the steam turbine for additional generation of electricity. This demonstrates a typical combined cycle where gas and steam turbines both are in operation for the utilization of gas as well as steam. UNDERGROUND COAL GASIFICATION (UCG): Underground coal gasification is essentially the same chemical conversion process used in surface coal gasification plants to convert solid coal into a mixture of useful gases known as SYNGAS. The main difference is that surface gasification occurs in a manufactured gasifier (reactor) whereas the gasifier for underground is a natural geological formation containing unmined coal. Vertical wells called injection wells and producer wells are drilled into a coal seam and linked together horizontally within the seam. Coal ignition is initiated through the use of an electric coil or gas firing near the surface of the coal seam. A compressed gasification agent (air or oxygen) is pumped into the injection well to allow for the combustion of coal. Combustion produces heat, carbon dioxide, and some SYNGAS through partial combustion. Through a series of chemical reactions involving pressure, heat, and carbon dioxide from combustion, steam (generated from water in the coal) and the carbon from the coal SYNGAS is produced. The gasification channel is normally divided into three zones: – Combustion / Oxidation Zone – Reduction Zone – Dry Distillation & Pyrolysis Zone In the oxidation zone, a multi-phase chemical reaction occurs involving oxygen in the gasification agents and carbon in the coal. The highest temperature occurs in the oxidation zone, due to the large release of energy during the initial reactions. In the reduction zone, the main reactions involve the reduction process. Within the distillation and pyrolysis zone, the coal seam is decomposed into multiple volatiles. Requisite Quality of Coal for Gasification: – Coal having volatile contents of around 35 % is advantageous – The lower rank of coal with a higher % of volatile matter reacts well with oxygen and steam to facilitate the reaction to take place in the gasifier. – Coal with a low moisture % is always beneficial. – The ash % around 30 with infusible ash is always preferred. Hence washed coal is primarily the best for gasification. – Fusible ash tends to serious clinking phenomena in the gasifier and is bound to slag with the lining of the gasifier. For dislodging clinkering, extra force is needed which causes undue loss of carbon in refuse. – Strongly coking coals are not recommended for gasification whereas the use of slightly coking coal in a gasifier is advantageous. Advantages of Underground Coal Gasifier (UCG) Vis-à-vis Overground Gasifier: – UCG offers the potential to use the energy stored in the coal deposits that are uneconomical to mine out the coal by conventional methods. – There is no need to mine out the coal, safety hazards associated with underground coal mining are eliminated. – UCG reduces significant disorders such as surface disturbances, land use conflicts, and avoidance of greenhouse gas production associated with coal mining. – UCG is a carbon capture process as it delivers an enriched CO2 stream suitable for carbon capture and storage. – UCG is a lower carbon-emitting process for power generation when compared to conventional coal-fired power stations. – Capital expenditure for UCG projects can be substantially lower than equivalent surface gasifier projects. Challenges of UCG System Vis-à-vis Overground Gasifier: – High chances of contamination of groundwater in the UCG system. – UCG operation cannot be controlled to the same extent as surface gasifier which poses the risk on account of high temperature and pressure in the cavity. – Some of the coal in UCG may have geologic and hydrologic features that increase environmental risks to unacceptable levels. – The economics of UCG-based power plants are not available as there is no UCG power plant in operation. – UCG carries huge environmental and geological risks. – The void created by UCG may cause significant deformation both in the remaining coal and surrounding rocks. – Heating, quenching, water flux, and potential roof and wall collapse may seriously compromise the integrity of the cavity. These are difficult to predict. – The high ash content of Indian Coal poses significant technical challenges for gasification process. – The UCG system cannot have a facility for washing the coal to meet the ash % requirement. – Underground gasifiers may not be as efficient as overground gasifiers. COAL GASIFICATION PLANTS IN INDIA: India’s foray into Coal Gasification began in the 1960s with the establishment of the Sindri Fertilizer Corporation of India (FCI) Plant. However, significant progress has been sporadic. Presently notable projects include: JINDAL STEEL & POWER LIMITED (JSPL), has been operating a coal-based Direct Reduced Iron (DRI) plant in Angul, Odisha since 2014. BHARAT HEAVY ELECTRICALS LIMITED (BHEL), A pilot plant at Tiruchirappalli generating 6.2 MW, facing challenges with high ash coal. THERMAX A Coal-to-Methanol Pilot Plant in Pune, funded by the Department of Science and Technology under NITI Aayog. TALCHER FERTILIZER LIMITED (TFL),