Equipments

Process Equipments

Heavy Media Cyclones / Dense Media Cyclones

Featuring exceptional wear resistance, comprehensive model options, substantial capacity, and dependable adherence to wear-resistant materials, our designs are tailored to various coal qualities, thereby ensuring precise cyclone separation

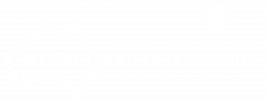

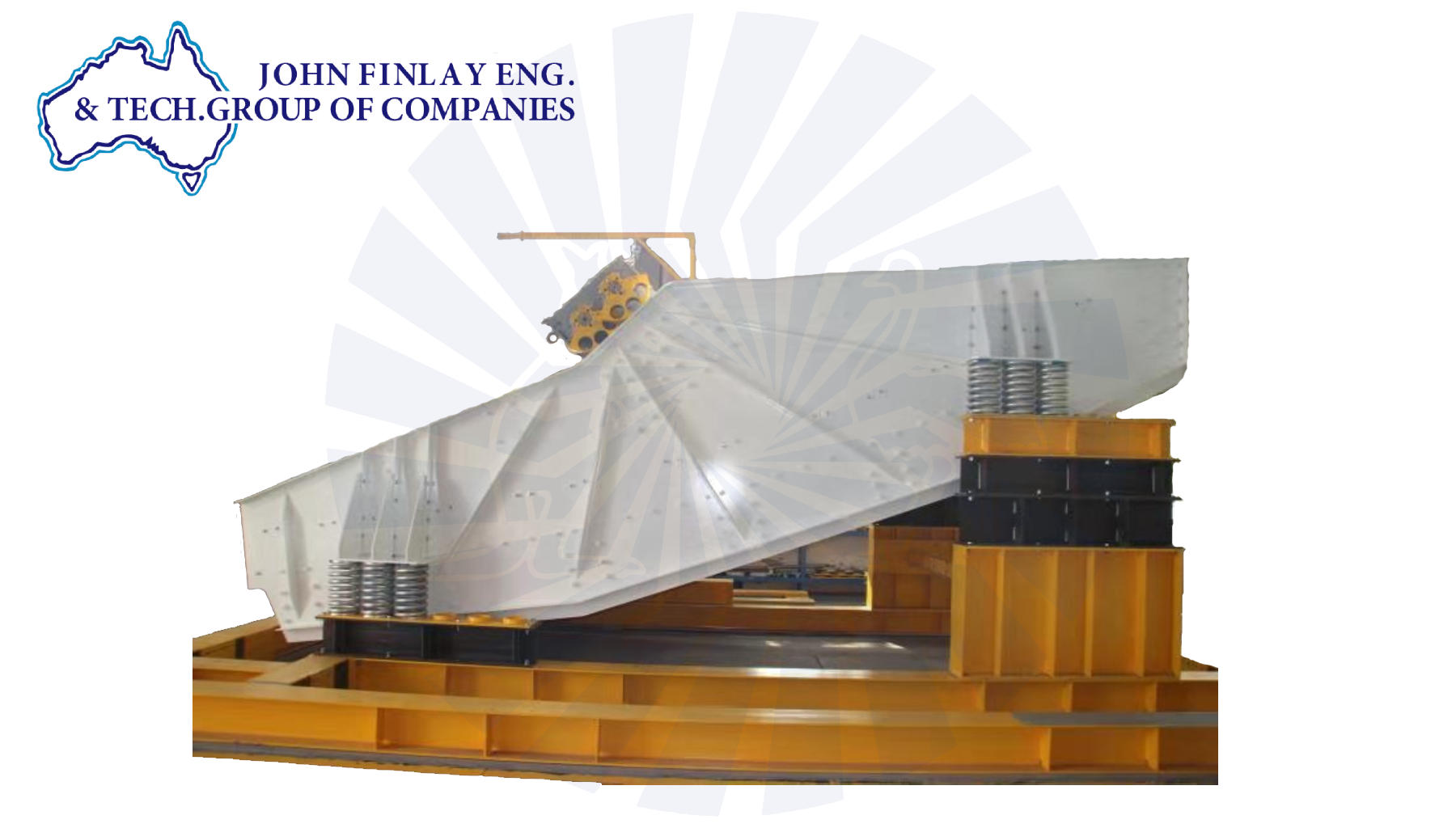

Vibrating Screens - Banana Screens

John Finlay's sturdy vibrating screens are purpose-built for demanding coal washery tasks, delivering high G-values and outstanding screening efficiency. Their design-production synergy is unmatched. With adjustable deck angles, they cater to precise service needs, featuring steep angles of 28-34° for raw coal separation screens and -5-50° for horizontal de-slime/de-reject screens, optimizing output without compromising screening efficiency.

Vertical & Horizontal Basket Centrifuges

John Finlay excels in centrifuge technology, offering Middling & Clean Coal Centrifuges and Slime Centrifuges with global design excellence and top-quality components. These machines ensure durability, high capacity, efficient dewatering, quiet operation, and adaptability to diverse coal qualities. Equipped with an Intelligent Early Warning Health Examination System, they optimize production, reduce costs, and guarantee reliability

Three Product Cyclones

Non-pressure Three-product DM cyclones prevent over-crushing, offer high capacity, efficient rejects discharge, and precise separation with durable corundum lining. Pressure feed Three-product DM cyclones provide high separation precision and adaptability for challenging coals, featuring wear-resistant lining. Our main product, Pressure Feed Two-product DM cyclones (1.1m to 1.5m diameter), ensure precise separation of clean coal, middling, and rejects.

Dense Medium Bath

Customizable models designed for client needs, featuring high alumina tiles and wear-resistant steel lining for durability. Chain rail designed for reduced wear, SEW reducer for reliability, and a casting alloy chain guide. Equipped with hydraulic chain tensioning and automatic lubrication. Interface for Intelligent Early Warning Health Examination System for online monitoring of key components

Magnetic Separators

New magnetic separators with imported components. High-coercivity magnetic blocks and optimized configuration create a powerful magnetic field for +99.9% recovery efficiency in dense medium coal preparation. The drum, made of 304SS, is non-magnetic and wear-resistant. It includes a liquid level adjustment device and a rinsing hole. The interface for the Intelligent Early Warning Health Examination System is reserved for effective machine monitoring and timely maintenance notifications.

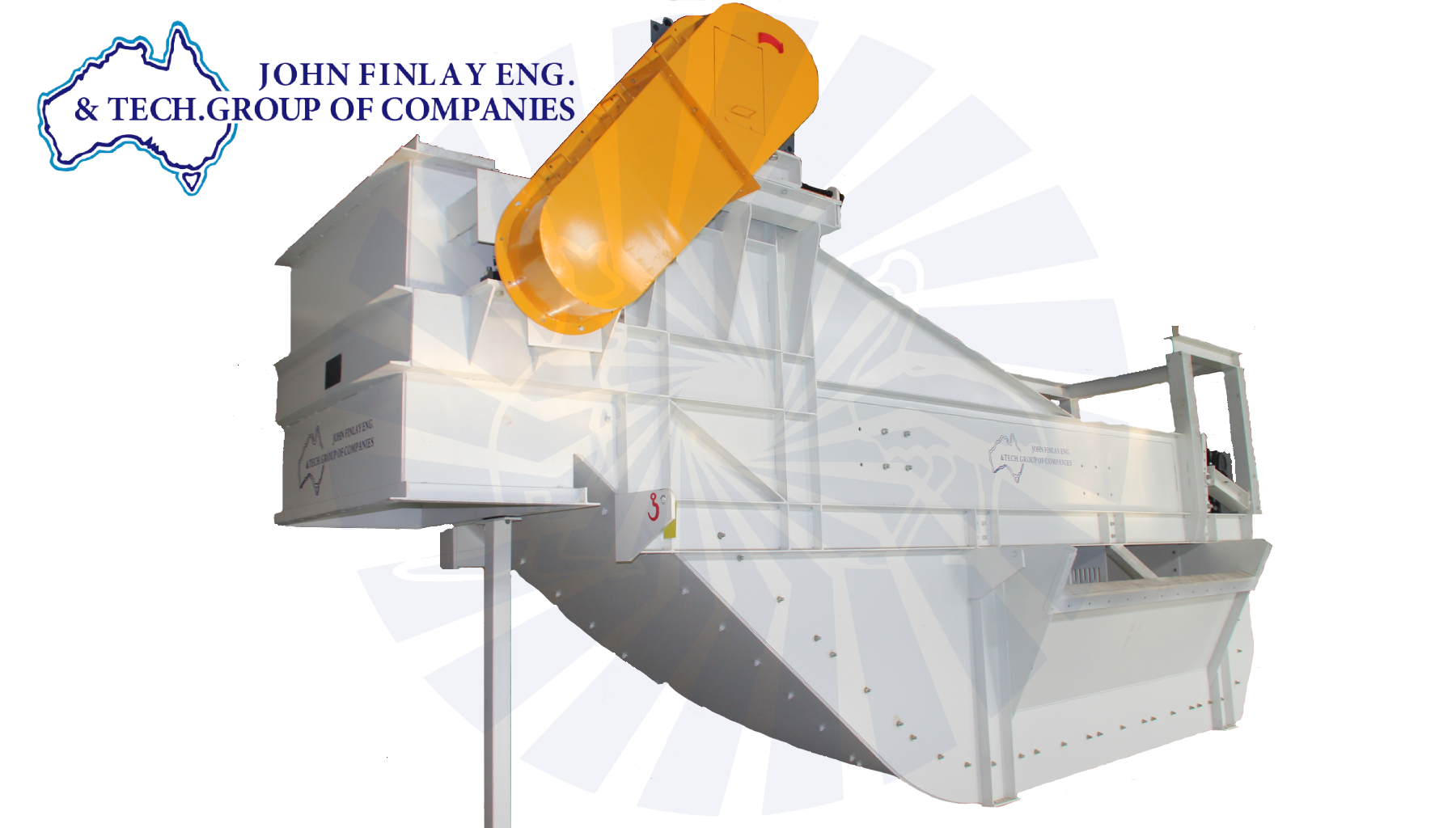

Intelligent Early Warning Sensors

John Finlay's Intelligent Early Warning Health Examination System for coal preparation plant equipment monitors key components, issues pre-warnings, and comes with a reserved interface. It ensures smooth operation and proactive maintenance by collecting stable and accurate data, analyzing machine health, and enabling timely action by equipment managers.

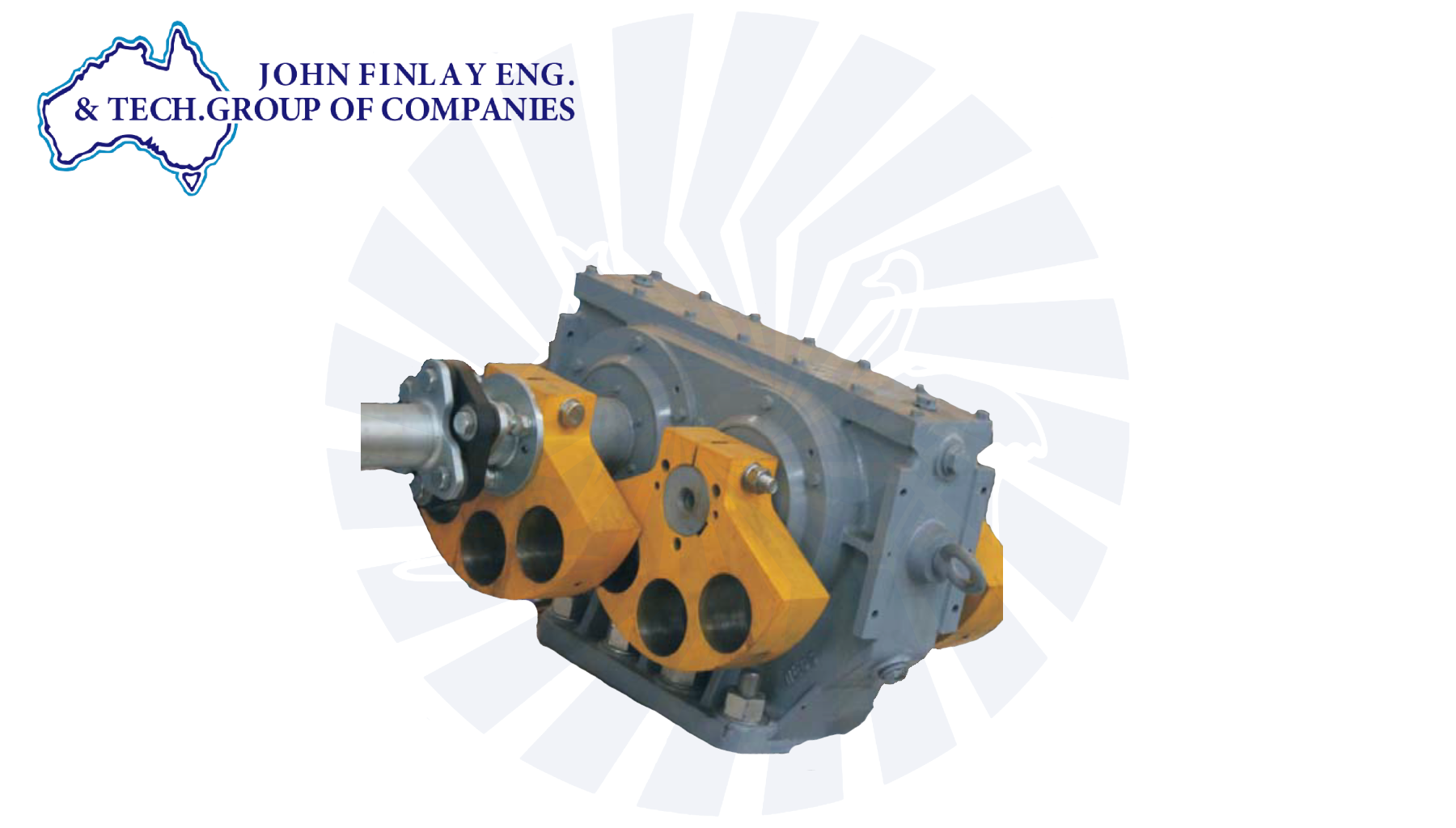

Exciters

Exciters, crucial for vibrating screen performance, are equipped with imported SKF or FAG bearings in our FE series, ensuring extended service life, low noise, temperature control, and adjustable exciting force. Our FEA series exciters, an upgraded version, offer maintenance-free operation by eliminating regular grease addition, preventing foreign object entry with breather removal, and addressing oil leakage concerns by removing cased seals, requiring only occasional grease replacement.

Filter Press

The filter press is a versatile tool used in various industries for solid-liquid separation. The device works by applying pressure to a filter cake. Which is formed by the solid particles in the liquid, to separate the liquid from the solid. Additionally, the filtration process of a filter press can be divided into three stages: pre-treatment, filtration, and post-treatment. The filter press has several advantages over other filtration methods.

Hydro Cyclone

Hydro Cyclone: Separates solids and liquids by centrifugal force for dewatering, desliming, and thickening in coal/mineral circuits. John Finlay’s optimized geometry with rubber or polyurethane linings delivers high-efficiency separation with low energy and maintenance—ideal for fine coal dewatering, thickening, and pre-flotation desliming.

Classifying Cyclone

The Classifying Cyclone separates fine particles by size and density using centrifugal force. Slurry is tangentially fed to form a vortex—coarse particles move to the underflow while fine ones rise to the overflow. John Finlay’s design ensures accurate size separation, high wear resistance, and easy maintenance, with diameters from 100–1200 mm. Its optimized feed chamber minimizes turbulence and bypass losses, making it ideal for coal, iron ore, and mineral classification, as well as desliming and dewatering.

Flotation Cell / Forth Flotation

John Finlay's XJM-S flotation machine is a self-priming air mechanical stirring flotation machine, which does not need additional air. During the impeller stirring process, it can effectively produce small bubbles, and the inflation rate is 1.0 cubic meter / square meter / minute, and the inflation uniformity is more than 90%. Power consumption per unit volume less than or equal to 2.5kw / m3

Water Only Cyclone (WOC)

Water-Only Cyclone: The John Finlay Water-Only Cyclone is designed for the gravity-based separation of fine coal and minerals using water as the medium. It efficiently separates particles by specific gravity difference under centrifugal force, making it ideal for coal beneficiation and fine coal cleaning applications.

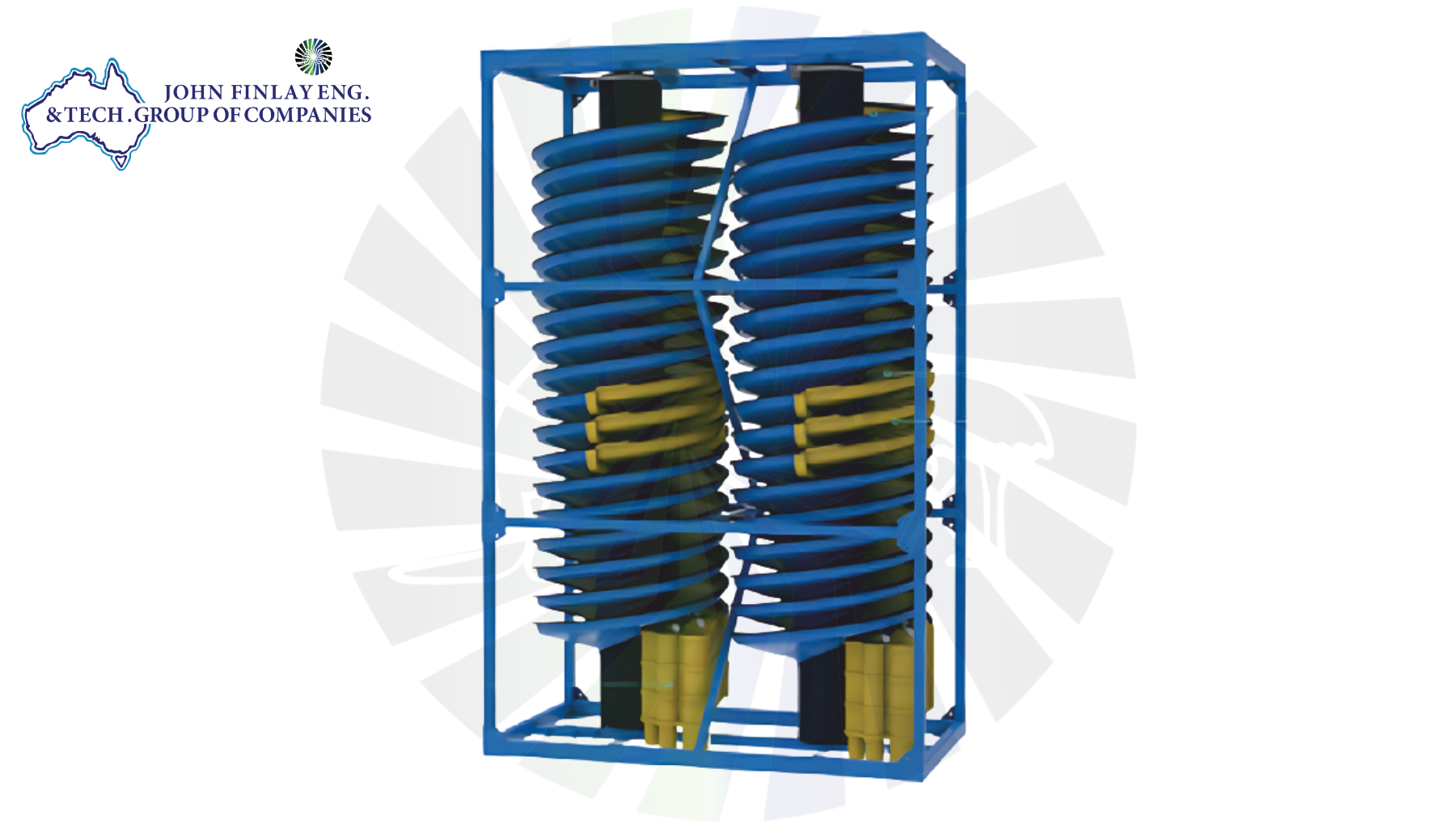

Spiral Concentrator

Spiral Concentrator: The John Finlay Spiral Concentrator is designed for gravity separation of fine coal and minerals based on specific gravity differences. It operates using a combination of gravity and centrifugal force, causing denser particles to move inward and lighter ones outward as slurry flows down the spiral trough. Stratified layers form along the spiral surface and are separated at discharge through adjustable splitters into concentrate, middling, and tailing streams.

Screen Bowl Centrifuge

Screen Bowl Centrifuge: Designed for efficient dewatering of fine coal, minerals, and tailings, the John Finlay Screen Bowl Centrifuge separates solids and liquids using centrifugal force to produce a low-moisture, high-recovery product. Feed slurry enters the rotating bowl, where solids form a sediment layer and are conveyed by a screw to the screen section for final drying. The clarified liquid exits through the overflow.

Teetered Bed Separator (TBS)

John Finlay Teetered Bed Separator (TBS): The John Finlay TBS is a high-efficiency density-based separation system for coarse slime beneficiation. It utilizes rising water flow to create a controlled turbulent environment, ensuring higher recovery rates, lower operating costs, and improved processing efficiency in coal and mineral beneficiation.

Intelligent Slurry Density Meter (LDC Series)

Intelligent Slurry Density Meter (LDC Series): The John Finlay LDC Series is an advanced non-nuclear, high-precision density monitoring system designed for continuous online measurement of slurry density in mineral and coal beneficiation applications. Built with high-chromium alloy wear-resistant bimetallic pipes, it offers exceptional durability and extended service life compared to conventional systems.

Vertical Vibrating Scroll Discharge Centrifuge

JFH Vertical Vibrating Scroll Discharge Centrifuge: The John Finlay JFH Vertical Vibrating Scroll Discharge Centrifuge is engineered for the dewatering and recovery of small coal and coarse slime. It delivers high throughput and low product moisture, making it ideal for fine particle separation in coal preparation plants. Its compact vertical construction provides high processing capacity and consistent performance, even with fine slurry or high-moisture feed.